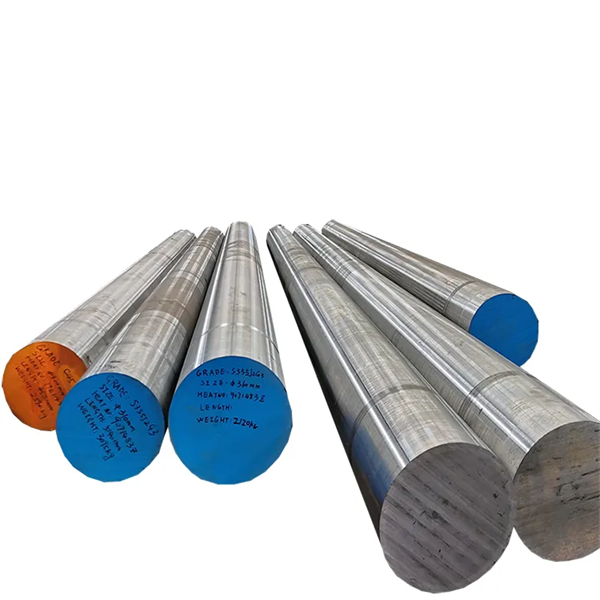

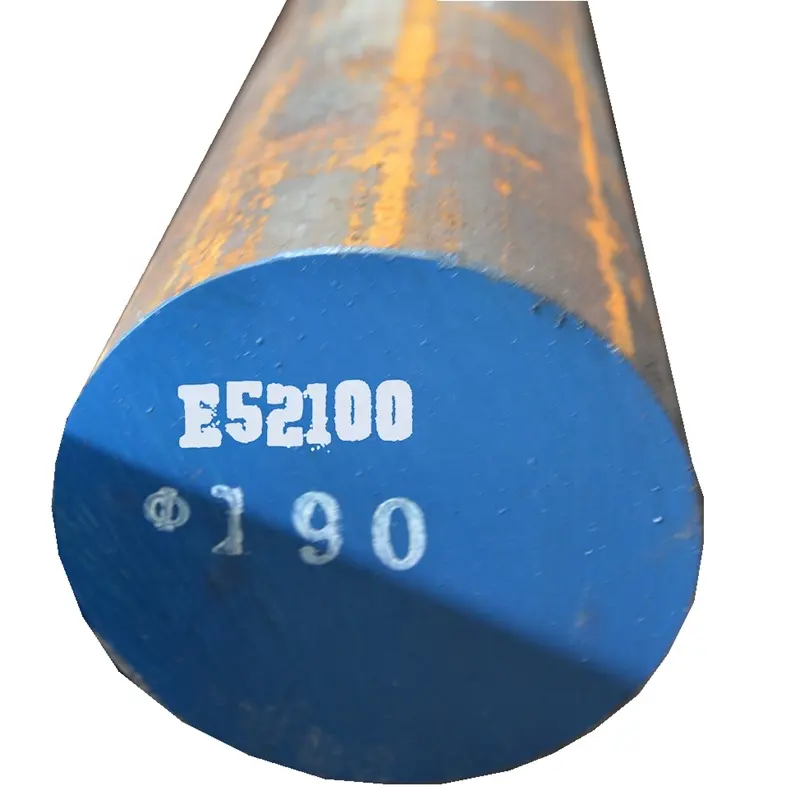

AISI SAE 4130 4140 4145H Steel Round Bar Hollow Rod

Features

4130 4135 4140 4145H simbi mbariro ishoma kabhoni alloy simbi.Ivo ndeveChrome-Molly alloy ine chromium uye molybdenum sevanosimbisa vamiririri.

4130 kutenderera simbi bhaa ine yakanaka basa kugona, kushoma kugadzirisa deformation, uye yakanakisa kuneta kuramba.Ndeyechikamu chesimbi yepakati nepamusoro-soro.Mushure mekurapa kwekupisa, 4140 ine simba rakanaka uye yakazara michina yemagetsi, yakanaka maitiro kugona, uye goho rakakura.Tembiricha yebasa i427 degrees Celsius.

4140 ine simba rakakwirira, kugona kuoma, kuoma, uye deformation panguva yekudzima.Iine simba guru rekukwira uye simba rekutsungirira pakupisa kukuru.Inoshandiswa kugadzira mafogi ayo anoda simba repamusoro uye akakurisa akadzimwa uye ane hasha zvikamu kupfuura 4135 simbi, senge magiya mahombe ekutambisa locomotive, booster transmission gears, rear axles, kubatanidza tsvimbo uye maspring clip ayo akaremerwa.

Tsanangudzo

| Product Name | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Material | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm kusvika 600mm | |

| Surface | Yakapendi nhema, Yakashama, Yakakwenenzverwa, Chrome Yakaputirwa | |

| Zvinotsanangurwa | Round bar | 8mm ~ 800mm |

| Angle bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Square bar | 4mm*4mm~100mm*100mm | |

| Flat bar | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800mm | |

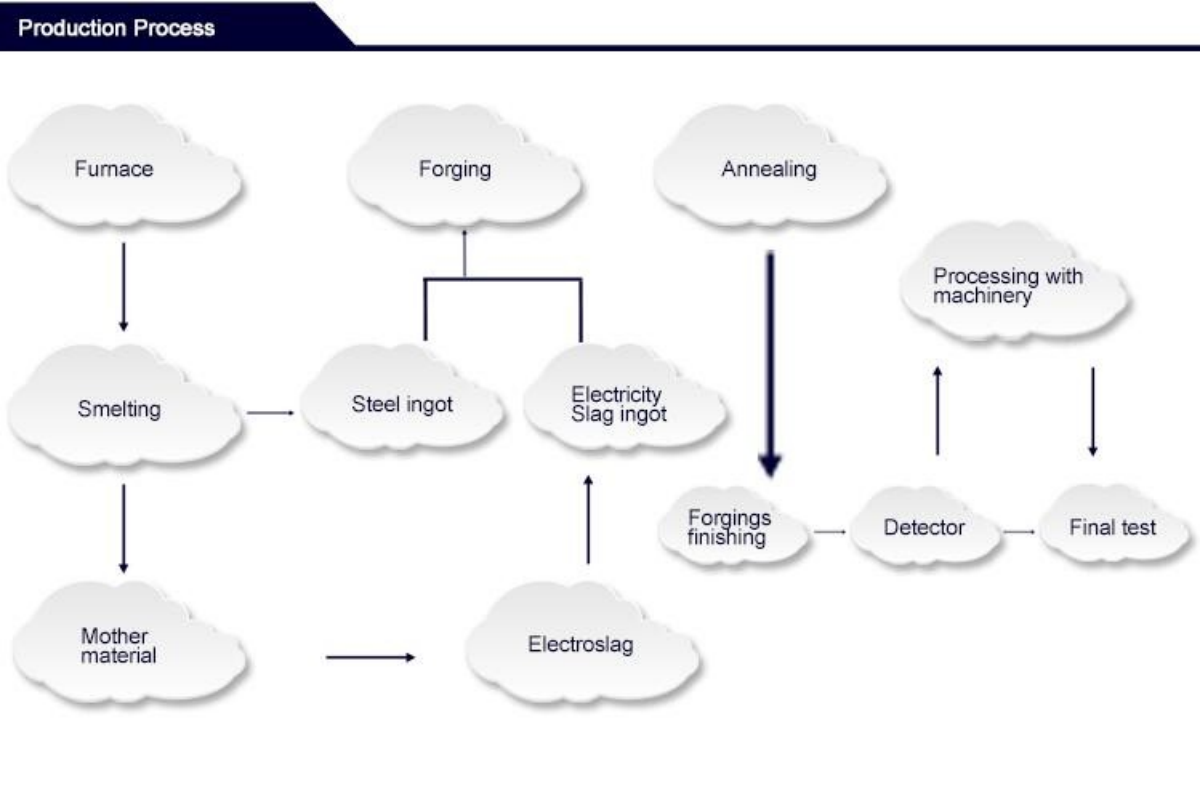

| Process | Choto chemagetsi chakanyungudutswa, chakagadzirwa uye chakanyungudutswa, bhara rakatenderedzwa rakatenderedzwa. | |

| Kuoma: | HBS 217Max (Yakasiyana nekurapa kupisa) | |

| UT Test | SEP 1921/84/2 C/c kirasi. | |

| Kushivirira | Dia -0/+ 0~5mm, Kukora -0/+ 0~5mm, Kufara: -0/+ 0~10mm. | |

| Urefu | 2m, 4m, 5.8m, 6m, 11.8m, 12m kana sezvinodiwa. | |

| Package | Seaworthy Packing. | |

| Equal dIfferent standard | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | SCM432 |

| 4145H | - | - | - |

Kuumbwa Kwemakemikari

| Muumbi weKemikari (%) | |||||||

| Giredhi | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties

| Hunhu: |

| 1.Low alloy simbi ine molybdenum uye chromium sevanosimbisa vamiririri; |

| 2.Zvakanaka kubva kune fusion weldability maonero; |

| 3.The alloy inogona kuomeswa nekurapa kwekupisa. |

Kushivirira

| Delivery Condition |

| 1.Hot yakakungurutswa |

| 2.Annealed |

| 3.Normalized |

| 4. Kudzima uye kuzvidzora |

Mamiriro ekupisa kupisa

1.Annealing: 880℃ Furnace kutonhora

2.Normalization: 880 ~ 870 ℃ Kutonhora kwemhepo

3.Kuomesa: 820 ~ 870℃ Mvura inotonhorera

4.Tempering: 550 ~ 650℃ Rapid kutonhora

Mechanical Properties inogona kuwanikwa nekusiyana kupisa kurapwa.

Package

1.Nemasumbu, bundle rimwe nerimwe rinorema pasi pematani matatu, kune zviduku zvekunze

dhayamita yakatenderedza bha, imwe neimwe bundle ine 4 - 8 simbi mitsetse.

2.20 tsoka mudziyo une dimension, kureba pasi pe6000mm

3.40 tsoka mudziyo une dimension, kureba pasi pe12000mm

4.Nemudziyo mukuru, Mutengo wekutakura wakaderera nehuwandu hwekutakura, uye hombe

saizi inorema haigone kutakurwa mumidziyo inogona kutakurwa nekutakura zvinhu zvakawanda

Kuvimbiswa kwehutano

1.Strict maererano neZvinodiwa

2. Muenzaniso: Muenzaniso unowanikwa.

3. Miedzo: Munyu wekupfapfaidza bvunzo / Tensile bvunzo / Eddy ikozvino / Kemikari yekuumbwa bvunzo zvinoenderana nechikumbiro chevatengi

4.Certificate: IATF16949, ISO9001, SGS nezvimwewo.

5. EN 10204 3.1 Chitupa