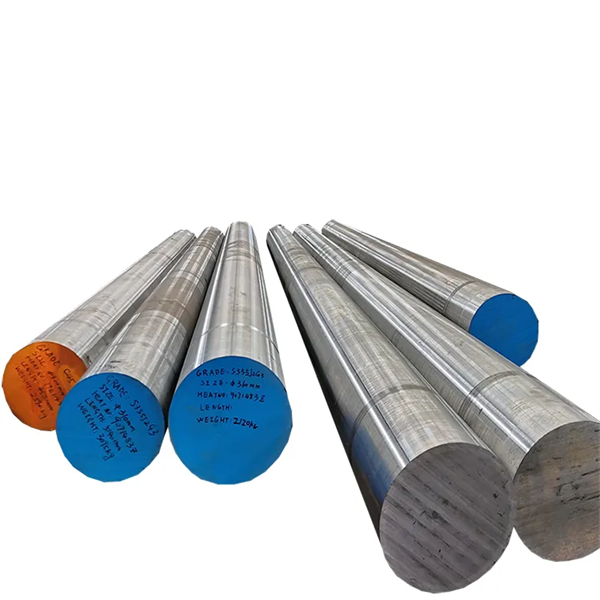

DIN 34crnimo6 simbi yakatenderedza bhaa 1.6582 simbi bhaa

Features

34CrNiMo6 Simbi yakakosha alloy engineering simbi giredhi senge paBS EN 10083-3:2006.34CrNiMo6 simbi ine simba rakawanda, kusimba kwakanyanya uye kunaka kuoma-kugona.

34CrNiMo6 inoshandiswa mumaindasitiri akadai sendege, mota, mota, uye kudzivirira kwenyika.34CrNiMo6 inogona kurapwa kupisa senge normalizing, kupisa, uye kudzima.Inoshandiswa kugadzira maketani, screws, giya, maoko, rollers, uye zvimwe zvakasiyana siyana zvemakanika.

Tsanangudzo

| Size | Round | Dia 6-1200mm |

| Plate/Flat/Block | Ukobvu | |

| 6mm-500mm | ||

| Upamhi | ||

| 20mm-1000mm | ||

| Process | EAF+LF+VD+Forged+Heat treatment(optional) | |

| Kurapa kwekupisa | Normalized ;Annealed ;Quenched ;Tempered | |

| Surface condition | Nhema;Peeled;Polished;Machined;Grind;Turned;Milled | |

| Delivery condition | Forged;Hot rolled;Cold drawn | |

| Test | Kusimba kwesimba, Goho resimba, kurebesa, nzvimbo yekudzikisa, kukosha kwekuita, kuoma, saizi yezviyo, ultrasonic bvunzo, US ongororo, magineti particle kuyedzwa, nezvimwe. | |

| Delivery nguva | 30-45 mazuva | |

| Application | 34CrNiMo6 inoshandiswa kune inorema muchina axle, turbine shaft blade, kuremerwa kwezvikamu zvekutapurirana, fasteners, crank shafts, magiya, pamwe neakaremerwa zvikamu zvekuvaka mota nezvimwe. | |

Kemikari yakagadzirwa (%)

| Carbon C | 0.3~0.38 |

| Silicon Si | 0.4 |

| Manganese Mn | 0.5~0.8 |

| Sulfur S | ≤ 0.035 |

| Phosphorus P | ≤ 0.025 |

| Chromium Cr | 1.3~1.7 |

| Nickel Ni | 1.3~1.7 |

| Molybdenum Mo | 0.15-0.3 |

Mechanical Properties

| Kusimba simba σ b (MPa) | 850~1400 |

| Goho simba σ s (MPa) | ≥690~1000 |

| Elongation δ (%) | ≥9~15% |

| Kuoma | 239~259 HB |

| Equal dIfferent standard | |

| Giredhi | Standard |

| 34CrNiMo6 (1.6582) | EN 10083-3 |

| 4337 | ASTM A29 |

Delivery condition

Kupisa forged bar, kazhinji mamiriro ekutumira anopisa akafukidzwa, annealed / QT rough yakatendeuka / Dema pamusoro.

Inopisa yakatenderedzwa bhaa, kazhinji iyo mamiriro ekutumira anopisa akakungurutswa, annealed / QT, Black surface.

Kushivirira

| Dhayamita(mm) | Kushivirira | ||

| Forged Simbi Round Bar | 80-600 | Black Surface: 0 ~ + 5 | Yakakasharara Yakagadzirwa kana Yakatendeuka: 0 ~ + 3 |

| 650-1200 | Black Surface: 0 ~ + 15 | Yakakasharara Yakagadzirwa kana Yakatendeuka: 0 ~ + 3 | |

| Kupisa Yakakungurutswa Simbi Round Bar | 16-310 | Black Surface:0~+1 | Yakabviswa:H11 |

| Cold Drawn Steel Round Bar | 6-100 | Black Surface:H11 | Yakabviswa:H11 |

Package

1.Nemasumbu, bundle rimwe nerimwe rinorema pasi pematani matatu, kune zviduku zvekunze

dhayamita yakatenderedza bha, imwe neimwe bundle ine 4 - 8 simbi mitsetse.

2.20 tsoka mudziyo une dimension, kureba pasi pe6000mm

3.40 tsoka mudziyo une dimension, kureba pasi pe12000mm

4.Nemudziyo mukuru, Mutengo wekutakura wakaderera nehuwandu hwekutakura, uye hombe

saizi inorema haigone kutakurwa mumidziyo inogona kutakurwa nekutakura zvinhu zvakawanda

Sitifiketi Yemhando: Yakapihwa muChirungu, kuwedzera mazwi akajairwa, maitiro ekugadzira, iyo mechaniki midziyo (simba regoho, kusimba kwesimba, kureba uye kuoma), forged ratio, UT bvunzo mhedzisiro, saizi yezviyo, nzira dzekurapa kupisa uye sampuli ye inoratidzwa paChitupa cheHunhu.

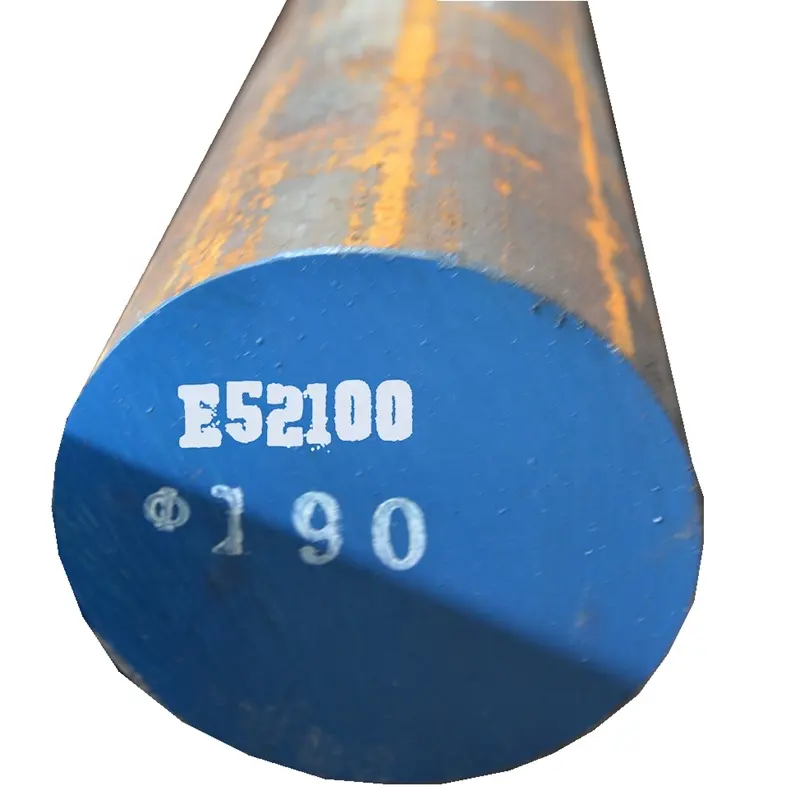

Kumaka: Heat Nha. ichatonhora uye Simbi giredhi, dhayamita (mm), kureba (mm), uye mugadziri LOGO uye huremu (kg) yakapendwa.

Kuvimbiswa kwehutano

1. Yakasimba maererano neZvinodiwa

2. Muenzaniso: Muenzaniso unowanikwa.

3. Miedzo: Munyu wekupfapfaidza bvunzo / Tensile bvunzo / Eddy ikozvino / Kemikari yekuumbwa bvunzo zvinoenderana nechikumbiro chevatengi

4. Chitupa: IATF16949, ISO9001, SGS nezvimwe.

5. EN 10204 3.1 Chitupa