Simbi Tube yeMota Zvikamu / SCM420H SCM440H SCM435 mota dzesimbi machubhu

Features

Material Giredhi:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C nezvimwewo.

Surface Treatment:

1.Bared

2.Black Painted (varnish coating)

3.Galvanized

4.Oiled

5.Maererano nevatengi.

JIS G3445 Precision simbi machubhu anonyanya kushandiswa mumotokari uye nemakina ezvikamu zvemotokari uye silinda.kushandiswa kwekumanikidza, uye zvakare kutakura chiutsi, mvura, gasi pombi mitsetse.

Kemikari yakagadzirwa

| Giredhi | Designation | Chikamu (%) | ||||||

| C | Si | Mn | P | S | Nb kana V | |||

| Grade 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | - |

| Grade 12 | A | STKM 12A | 0.20 max. | 0.35 max. | 0.6 max. | 0.04 max. | 0.04 max. | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Grade 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30~0.90 | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Grade 14 | A | STKM 14A | 0.30 max. | 0.35 max. | 0.30 ~ 1.00 | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14C | |||||||

| Grade 15 | A | STKM 15A | 0.25~0.35 | 0.35 max. | 0.30 ~ 1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 15C | |||||||

| Grade 16 | A | STKM 16A | 0.35~0.45 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Grade 17 | A | STKM 17A | 0.45~0.55 | 0.40 max. | 0.40~1.00 | 0.040 max. | 0.040 max. | - |

| C | STKM 17C | |||||||

| Grade 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Grade 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Grade 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Mechanical properties

| Steel Giredhi | Goho Simba (Mpa) | Tensile Strength (Mpa) | Elongation (%) | |

| Zita | Aihwa. | ReH (min) | Rm(min) | A(min) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 | 20 |

| STKM13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

Kushivirira

| SIZE | Kushivirira kunobvumirwa | Kushivirira Kwakakosha | ||

| OD | WT | OD | WT | |

| 4mm-20mm | ± 0.25mm | <3mm± 0.3mm;

≥3mm ±10%

| ± 0.05mm | ± 0.05mm |

| 20mm-30mm | ± 0.25mm | ±0.08mm | ±0.08mm | |

| 31mm-40mm | ± 0.25mm | ± 0.10mm | ±0.08mm | |

| 41mm-49mm | ± 0.25mm | ± 0.15mm | ± 0.15mm | |

| 50mm-80mm | ±0.5% | ± 0.20mm | ± 0.20mm | |

| 81mm-120mm | ±0.5% | ± 0.30mm | ± 0.30mm | |

Delivery condition

| Designation | Symbol | Tsanangudzo |

| Kutonhora kwapera (zvakaoma) | BK(+C) | Machubhu haaitirwe kurapwa kwekupisa zvichitevera kutonhora kwekupedzisira kuumbwa uye, nekudaro, kune yakanyanya kupikisa deformation |

| Kutonhora kwapera (Kupfava) | BKW | Iyo yekupedzisira kupisa kurapwa inoteverwa neinotonhora kudhirowa kunosanganisira kushoma deformation.Kuenderera mberi kwakakodzera kugadzirisa kunobvumira imwe dhigirii yekutonhora kuumba (semuenzaniso kukotama, kuwedzera) |

| (+LC) | ||

| Kutonhora kwapera uye kushushikana-kubvisa | BKS(+SR) | Kurapa kwekupisa kunoshandiswa zvichitevera kutonhora kwekupedzisira kuumba maitiro.Zvichienderana nemamiriro ekugadzirisa akakodzera, kuwedzera kwekunetseka kwakasara kunobatanidzwa kunogonesa kuumba uye kugadzira kune imwe nhanho. |

| Annealed | GBK(+A) | Iyo yekupedzisira Cold kuumba maitiro inoteverwa neannealing mumhepo inodzorwa. |

| Normalized | NBK(+N) | Iyo yekupedzisira inotonhora kuumba maitiro inoteverwa neannealing pamusoro peiyo yepamusoro shanduko nzvimbo munzvimbo inodzorwa. |

Delivery condition

| Designation | Symbol | Tsanangudzo |

| Kutonhora kwapera (zvakaoma) | BK(+C) | Machubhu haaitirwe kurapwa kwekupisa zvichitevera kutonhora kwekupedzisira kuumbwa uye, nekudaro, kune yakanyanya kupikisa deformation |

| Kutonhora kwapera (Kupfava) | BKW | Iyo yekupedzisira kupisa kurapwa inoteverwa neinotonhora kudhirowa kunosanganisira kushoma deformation.Kuenderera mberi kwakakodzera kugadzirisa kunobvumira imwe dhigirii yekutonhora kuumba (semuenzaniso kukotama, kuwedzera) |

| (+LC) | ||

| Kutonhora kwapera uye kushushikana-kubvisa | BKS(+SR) | Kurapa kwekupisa kunoshandiswa zvichitevera kutonhora kwekupedzisira kuumba maitiro.Zvichienderana nemamiriro ekugadzirisa akakodzera, kuwedzera kwekunetseka kwakasara kunobatanidzwa kunogonesa kuumba uye kugadzira kune imwe nhanho. |

| Annealed | GBK(+A) | Iyo yekupedzisira Cold kuumba maitiro inoteverwa neannealing mumhepo inodzorwa. |

| Normalized | NBK(+N) | Iyo yekupedzisira inotonhora kuumba maitiro inoteverwa neannealing pamusoro peiyo yepamusoro shanduko nzvimbo munzvimbo inodzorwa. |

| High Precision Steel Tubes muStock | ||||||||||

| OD | Hukobvu(mm) | |||||||||

| mm | ||||||||||

| 4 | 4*1 | |||||||||

| 6 | 6*1 | 6*1.5 | 6*2 | |||||||

| 8 | 8*1 | 8*1.5 | 8*2 | |||||||

| 10 | 10*1 | 10*1.5 | 10*2 | 10*2.5 | ||||||

| 12 | 12*1 | 12*1.5 | 12*2 | 12*2.5 | 12*3 | |||||

| 14 | 14*1 | 14*1.5 | 14*2 | 14*2.5 | 14*3 | |||||

| 15 | 15*1 | 15*1.5 | 15*2 | 15*2.5 | 15*3 | 15*3.5 | ||||

| 16 | 16*1 | 16*1.5 | 16*2 | 16*2.5 | 16*3 | 16*3.5 | 16*4 | 16*4.5 | ||

| 18 | 18*1 | 18*1.5 | 18*2 | 18*2.5 | 18*3 | 18*3.5 | 18*4 | 18*4.5 | ||

| 20 | 20*1 | 20*1.5 | 20*2 | 20*2.5 | 20*3 | 20*3.5 | 20*4 | 20*4.5 | 20*5 | |

| 22 | 22*1 | 22*1.5 | 22*2 | 22*2.5 | 22*3 | 22*3.5 | 22*4 | 22*4.5 | 22*5 | |

| 25 | 25*1 | 25*1.5 | 25*2 | 25*2.5 | 25*3 | 25*3.5 | 25*4 | 25*4.5 | 25*5 | |

| 28 | 28*1 | 28*1.5 | 28*2 | 28*2.5 | 28*3 | 28*3.5 | 28*4 | 28*4.5 | 28*5 | |

| 30 | 30*1 | 30*1.5 | 30*2 | 30*2.5 | 30*3 | 30*3.5 | 30*4 | 30*4.5 | 30*5 | 30*6 |

| 32 | 32*1.5 | 32*2 | 32*2.5 | 32*3 | 32*3.5 | 32*4 | 32*4.5 | 32*5 | 32*6 | |

| 34 | 34*1.5 | 34*2 | 34*2.5 | 34*3 | 34*3.5 | 34*4 | 34*4.5 | 34*5 | 34*6 | |

| 35 | 35*1.5 | 35*2 | 35*2.5 | 35*3 | 35*3.5 | 35*4 | 35*4.5 | 35*5 | 35*6 | |

| 38 | 38*2 | 38*2.5 | 38*3 | 38*3.5 | 38*4 | 38*4.5 | 38*5 | 38*6 | ||

| 40 | 40*2 | 40*2.5 | 40*3 | 40*3.5 | 40*4 | 40*4.5 | 40*5 | 40*6 | ||

| 42 | 42*2 | 42*2.5 | 42*3 | 42*3.5 | 42*4 | 42*4.5 | 42*5 | 42*6 | ||

| 45 | 45*2 | 45*2.5 | 45*3 | 45*3.5 | 45*4 | 45*4.5 | 45*5 | 45*6 | ||

| 46 | 46*2 | 46*2.5 | 46*3 | 46*3.5 | 46*4 | 46*4.5 | 46*5 | 46*6 | ||

| 48 | 48*2 | 48*2.5 | 48*3 | 48*3.5 | 48*4 | 48*4.5 | 48*5 | 48*6 | ||

| 50 | 50*2 | 50*2.5 | 50*3 | 50*3.5 | 50*4 | 50*4.5 | 50*5 | 50*6 | ||

| 54 | 54*2.5 | 54*3 | 54*3.5 | 54*4 | 54*4.5 | 54*5 | 54*6 | |||

| 60 | 60*2.5 | 60*3 | 60*3.5 | 60*4 | 60*4.5 | 60*5 | 60*6 | |||

| 65 | 65*3 | 65*3.5 | 65*4 | 65*4.5 | 65*5 | 65*6 | ||||

| 75 | 75*3.5 | 75*4 | 75*4.5 | 75*5 | 75*6 | |||||

| 76 | 76*4 | 76*4.5 | 76*5 | 76*6 | ||||||

| 89 | 89*6 | |||||||||

| Ongorora: Tinogona kugadzira mamwe saizi sezvinodiwa zvako.Kurapa Kwepamusoro: Kupenya, Galvanized, Phosphate etc. | ||||||||||

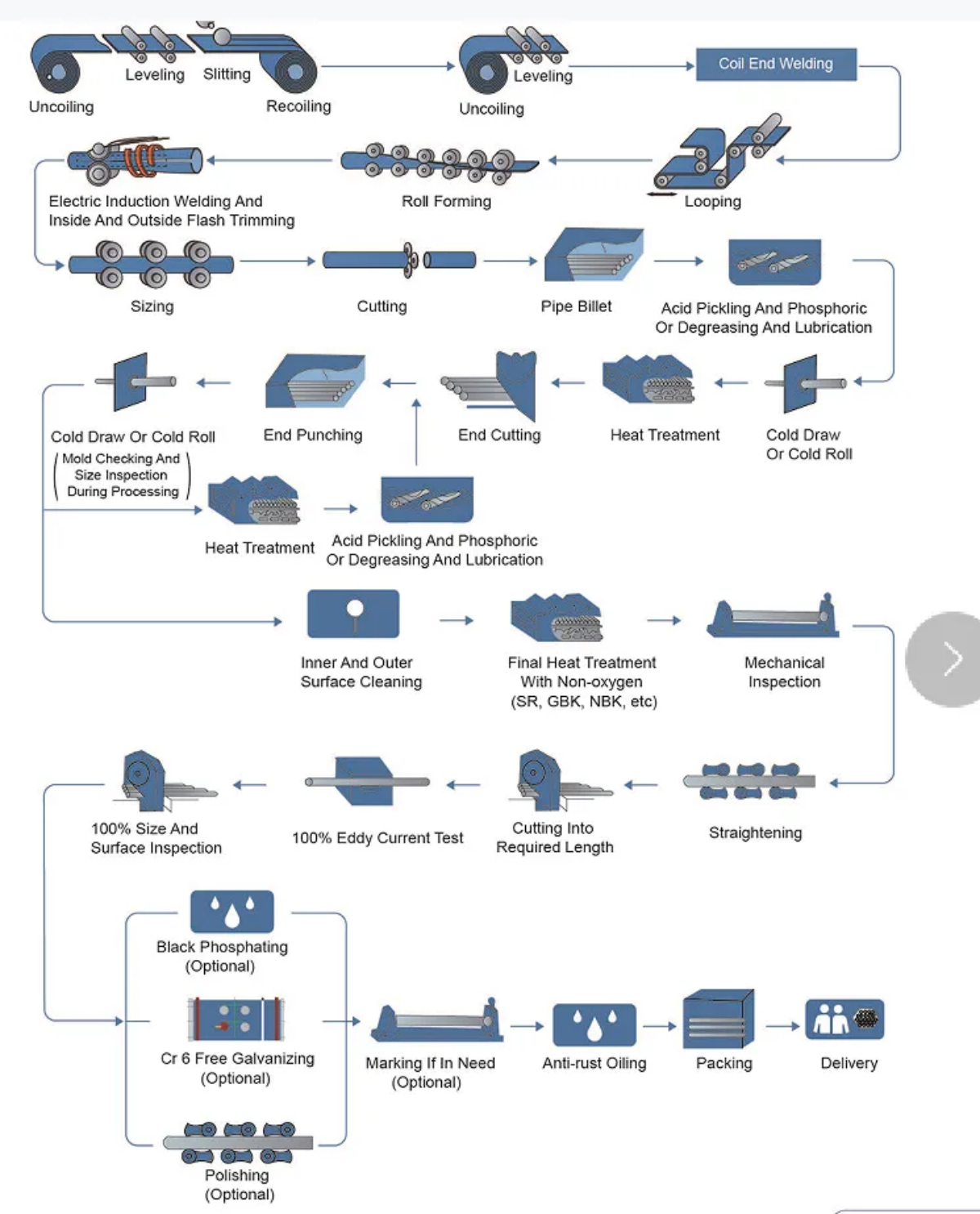

Manufacture Process

Zvakanakira

Simbisa kuongororwa kwezvigadzirwa muchikamu chega chega chekugadzira, chine midziyo yekuyedza yakakwana: isingaparadze eddy ikozvino kuyedza, yakanyanya kumanikidza kuramba yekuyedza muchina, universal mechanic tensile yekuyedza muchina, kubhenda flattening flares yekuyedza muchina, hutsanana analyzer, simbi element analyzer, nezvimwe. Sangana nemakanika ezvivakwa zvezvigadzirwa, process performance test, ipa vimbiso ine simba kune zvigadzirwa zvinokodzera.

Kuvimbiswa kwehutano

1. Yakasimba maererano neJIS G3445 Standard kana mamwe maitiro.

2. Sample: Sample is free for test.

3. Miedzo: Munyu wekupfapfaidza bvunzo / Tensile bvunzo / Eddy ikozvino / Kemikari yekuumbwa bvunzo zvinoenderana nechikumbiro chevatengi

4.Certificate: IATF16949, ISO9001, SGS nezvimwewo.

5.EN 10204 3.1 Chitupa