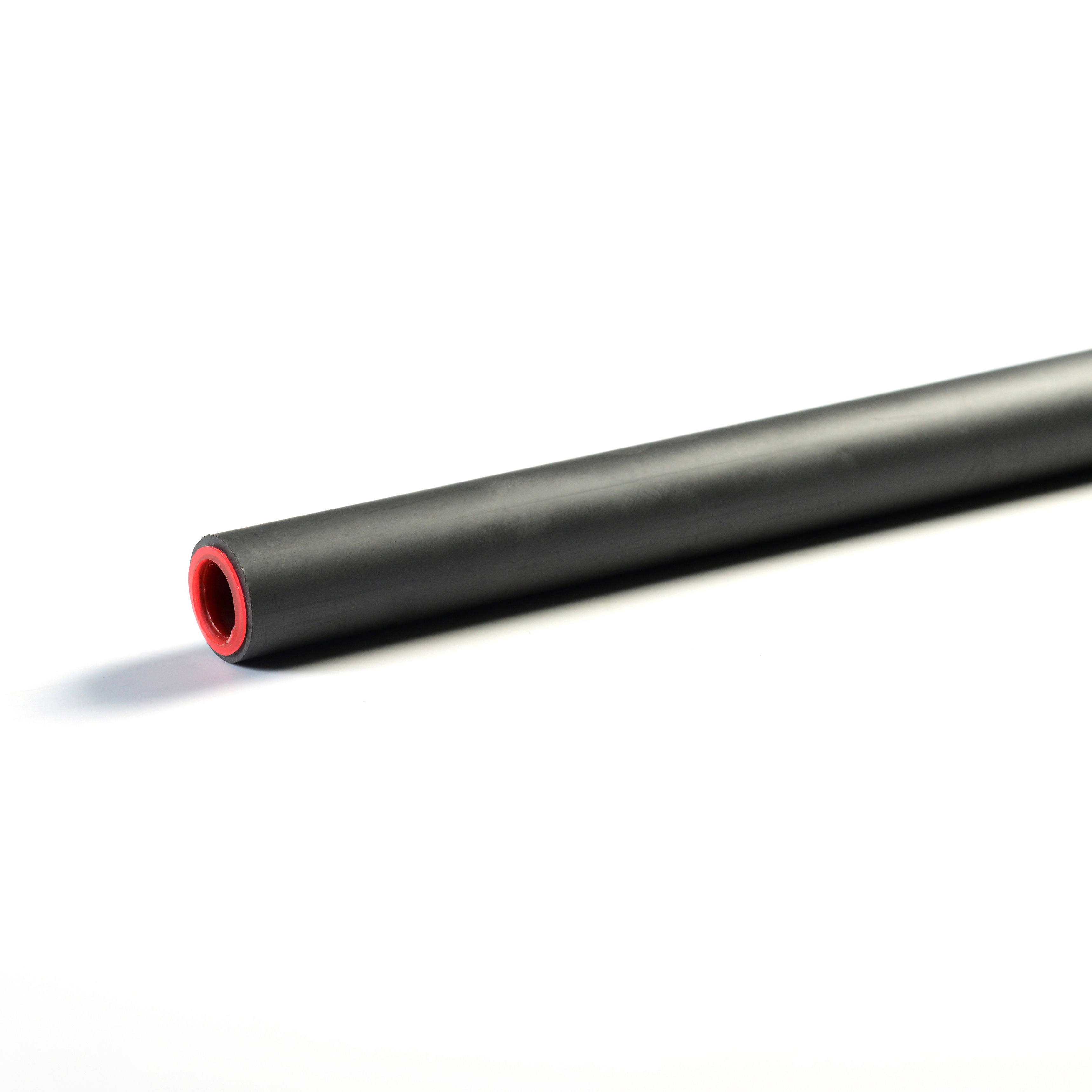

Precision phosphatedpombirudzi rutsva rwepombi isingapfekeki, iyo inoshandisa nzira yekutenderera nesting composite.Iyo inoumbwa neiyo mechanic basa rekutenderera nesting inoumbwa yezvinhu zviviri zvakasiyana zvesimbi simbi pamwe chete, nesainzi kushandisa yekunze base pombi madziro ukobvu kutakura kumanikidza kwekushanda kwepombi system, uye kushandisa iyo yakavharwa inodzivirira corrosion alloy pombi kutakura corrosion zvinodiwa zvepipeline system.

Kuenzaniswa neyechinyakare kupfeka-resistant alloy cast iron, kupfeka-resistant alloy cast simbi, simbi ceramic composite pombi, uye pombi yedombo yakakandwa, iyi phosphat chaiyo.ed pombi ine zvinotevera zvakanakira.

1. Good kupfeka resistance.

2. High pressure resistance, yakakodzera kukwirira kwepamusoro.

3. Mucheka wemukati wakanyatsobatanidzwa nekunze kwesimbi pombi, uye nzira yakakosha inosarudzwa kuti iite fusion yekubatanidza pakati pezvikamu zvakasanganiswa, kuve nechokwadi chekuvimbika kwekushanda.

4. Iine kupikisa kwakanaka kune mechanical shock uye thermal shock.

5. Yakanakira mudziyo kubatana.Flanges uye majoini anochinjika anogona kushandiswa pakubatanidza, uye anogona kutemwa kana kubatanidza pakuda.

Kuwanda kwekushandisa:

Coal powder conveying system, mvura yakaoma dota inotakura pombi, uye dombo remarasha system mumagetsi ekupisa.

Mamwe masisitimu ekufambiswa kwepneumatic ehupfu

Hydraulic slag yekufambisa system uye slurry yekufambisa ine yakakura particle size

Kutakurwa kwezvinhu zvakasiyana-siyana zvemigodhi

1. Phosphating effect

(1) Mhedzisiro yephosphating isati yapfeka

① Wedzera kunamatira pakati peiyo yekubikira layer (senge pendi yekupotera) uye workpiece.

② Kuvandudza kushorwa kwehuputi hwepamusoro peiyo workpiece mushure mekuputira.

③ Kuvandudza kushongedzwa.

(2) Mhedzisiro yekusavhara phosphating

① Kuvandudza kupfeka kuramba kweiyo workpiece.

② Ita shuwa kutsetseka kweiyo workpiece panguva yekugadzira.

③ Kuvandudza kushorwa kweiyo workpiece.

2. Kushandiswa kwephosphating

Simbi phosphating inonyanya kushandiswa kudzivirira corrosion uye seyakadzika firimu repende.

(1) Phosphating firimu rekudzivirira ngura

① Protective phosphating firimu rinoshandiswa kurapa corrosion kudzivirira kwezvikamu zvesimbi.Mhando yefirimu yephosphating inogona kuva zinc kana manganese.Huremu pachikamu chechikamu che membrane ndeye 10-40 g / m2.Isa anti rust mafuta, girisi, wakisi, nezvimwewo mushure me phosphating.

② Phosphating firimu repende substrate

Wedzera kunamatira uye kudzivirira pakati pepende firimu uye simbi workpieces.Mhando yefirimu ye phosphating inogona kuva zinc based kana zinc calcium based.The unit area mass of the phosphating film is 0.2-1.0 g/m2 (inoshandiswa kuzasi kwependi pane yakakura deformation steel parts);1-5 g/m2 (yakashandiswa pazasi pendi pendi pane general simbi zvikamu);5-10 g/m2 (yependi base layer yesimbi zvikamu zvisingaite deformation).

(2) Phosphate coating yekutonhora kushanda zvakanaka

Firimu uremu pachikamu nharaunda yesimbi waya uye welded simbi pombi kudhirowa iri 1-10 g/m2;Iyo firimu uremu pachikamu chechikamu cheiyo precision phosphating chubhu kudhirowa ndeye 4-10 g/m2;Iyo firimu huremu pachikamu chechikamu chekutonhora extrusion kuumbwa kwezvikamu zvesimbi yakakura kupfuura 10 g/m2.

(3) Phosphate coating yekudzikisa kukakavara

Phosphating firimu inogona kuderedza friction.Kazhinji, manganese based phosphating inoshandiswa, uye zinc based phosphating inogona kushandiswa zvakare.Kune maworkpieces ane madiki akasimba anokodzera magapu, kuwanda kweiyo phosphating firimu ndeye 1-3 g/m2;Kune maworkpieces ane mahombe anosimba anokodzera gapu (giya regiya), huwandu hwefirimu rephosphating ndeye 5-20 g/m2.

(4) Phosphate coating yemagetsi ekudzivirira

Kazhinji, zinc based phosphating inoshandiswa.Inoshandiswa kune silicon wafer phosphating kurapwa mumamotor uye transformers.

Nguva yekutumira: Aug-24-2023