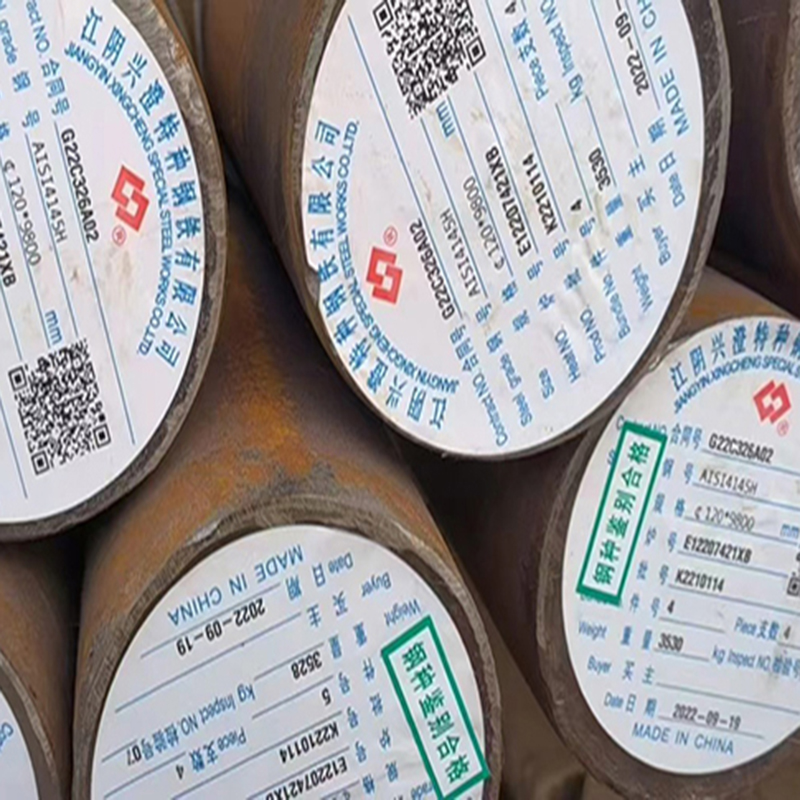

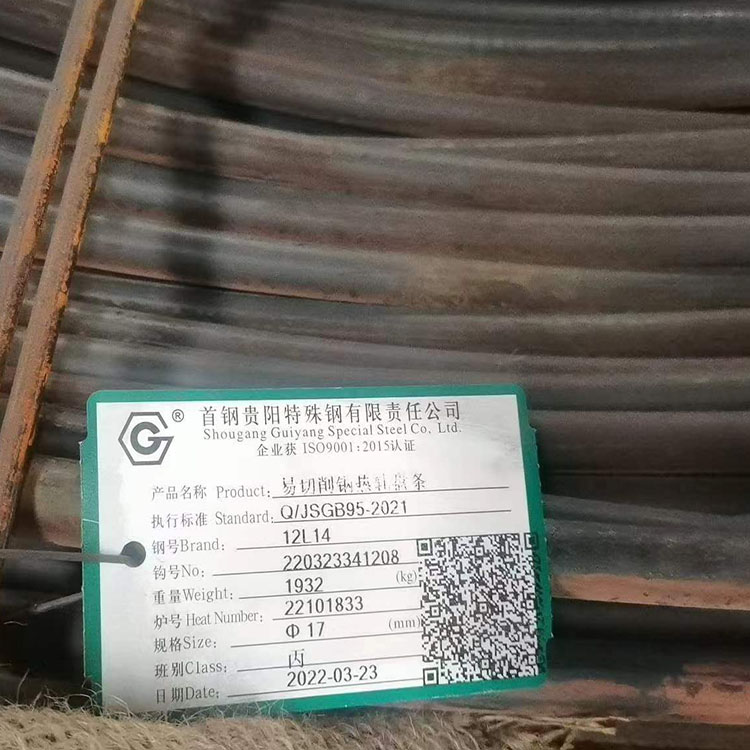

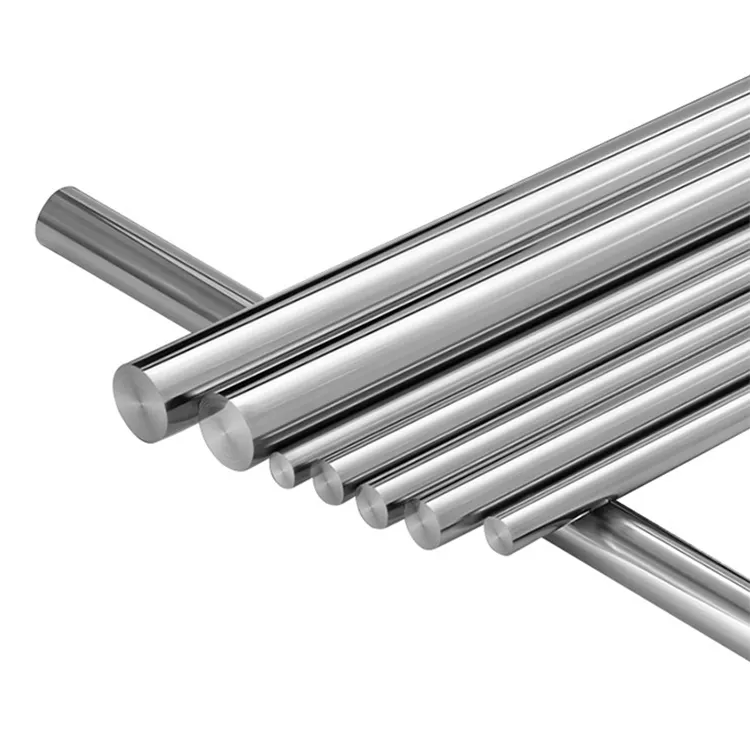

SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar

Isu tinotevera manejimendi ehutongi hwekuti "Hunhu hwakasarudzika, Rubatsiro rwakanyanya, mukurumbira ndewekutanga", uye tichagadzira nemoyo wese kubudirira nevatengi vese veSAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Isu tiri kuramba tichivhima kuti titange hukama vatengesi vatsva kupa nzira inofambira mberi uye ine hungwaru kune vatengi vedu vanokoshesa.

Isu tinotevera manejimendi ehutongi hwekuti "Hunhu hwakasarudzika, Rubatsiro rwakanyanya, mukurumbira ndewekutanga", uye tichagadzira nemoyo wese kubudirira uye kugovana budiriro nevatengi vese.4130 Steel Bar, Tinovimba tinogona kumisikidza kushandira pamwe kwenguva refu nevatengi vese.Uye ndinovimba isu tinogona kuvandudza kukwikwidza uye kuwana iyo yekukunda-kukunda mamiriro pamwe nevatengi.Isu tinogamuchira nemoyo wese vatengi vanobva kumativi ese enyika kuti vatibate pane chero chaunoda!

Features

4130 4135 4140 4145H simbi mbariro ishoma kabhoni alloy simbi.Ivo ndeveChrome-Molly alloy ine chromium uye molybdenum sevanosimbisa vamiririri.

4130 kutenderera simbi bhaa ine yakanaka basa kugona, kushoma kugadzirisa deformation, uye yakanakisa kuneta kuramba.Ndeyechikamu chesimbi yepakati nepamusoro-soro.Mushure mekurapa kwekupisa, 4140 ine simba rakanaka uye yakazara michina yemagetsi, yakanaka maitiro kugona, uye goho rakakura.Tembiricha yebasa i427 degrees Celsius.

4140 ine simba rakakwirira, kugona kuoma, kuoma, uye deformation panguva yekudzima.Iine simba guru rekukwira uye simba rekutsungirira pakupisa kukuru.Inoshandiswa kugadzira mafogi ayo anoda simba repamusoro uye akakurisa akadzimwa uye ane hasha zvikamu kupfuura 4135 simbi, senge magiya mahombe ekutambisa locomotive, booster transmission gears, rear axles, kubatanidza tsvimbo uye maspring clip ayo akaremerwa.

Tsanangudzo

| Product Name | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Material | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Standard | GB/T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm kusvika 600mm | |

| Surface | Yakapendi nhema, Yakashama, Yakakwenenzverwa, Chrome Yakaputirwa | |

| Zvinotsanangurwa | Round bar | 8mm ~ 800mm |

| Angle bar | 3mm*20mm*20mm~12mm*800mm*800mm | |

| Square bar | 4mm*4mm~100mm*100mm | |

| Flat bar | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800mm | |

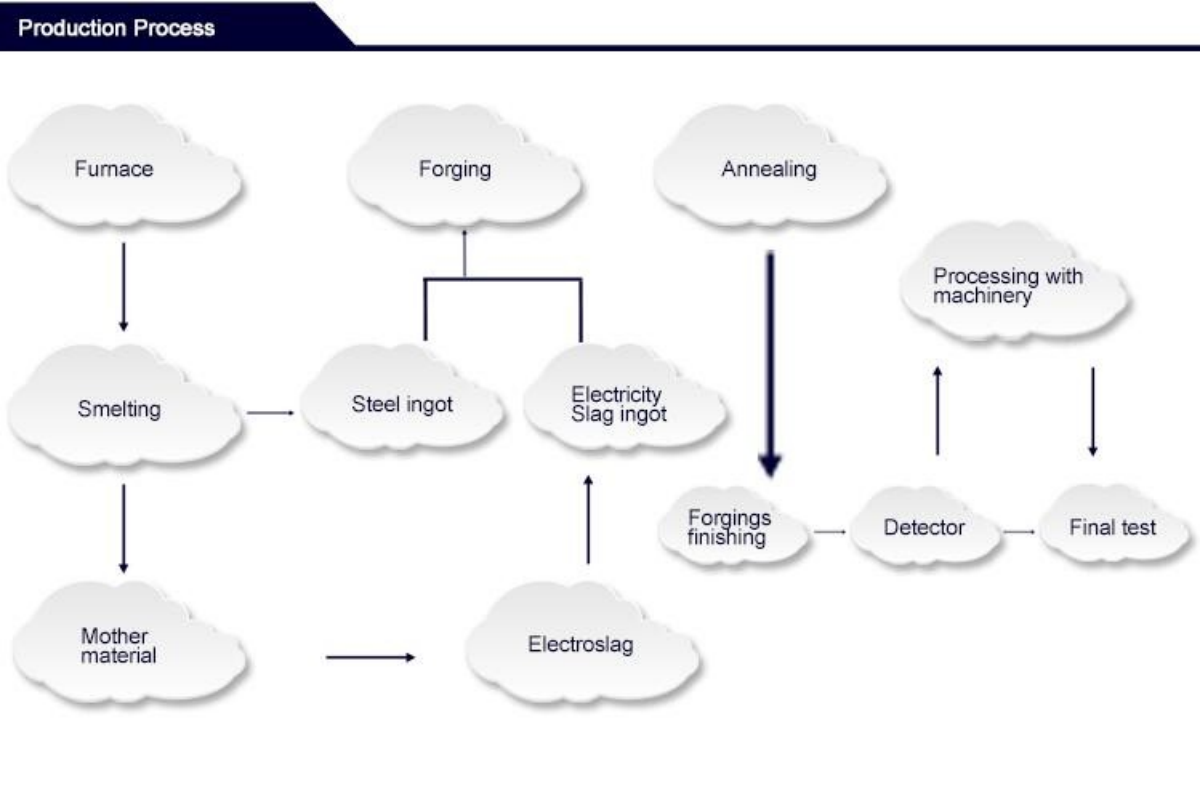

| Process | Choto chemagetsi chakanyungudutswa, chakagadzirwa uye chakanyungudutswa, bhara rakatenderedzwa rakatenderedzwa. | |

| Kuoma: | HBS 217Max (Yakasiyana nekurapa kupisa) | |

| UT Test | SEP 1921/84/2 C/c kirasi. | |

| Kushivirira | Dia -0/+ 0~5mm, Kukora -0/+ 0~5mm, Kufara: -0/+ 0~10mm. | |

| Urefu | 2m, 4m, 5.8m, 6m, 11.8m, 12m kana sezvinodiwa. | |

| Package | Seaworthy Packing. | |

| Equal dIfferent standard | |||

| AISI | GB | DIN | JIS |

| 4130 | 30CrMo | 1.7218 | SCM420 |

| 4140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| 4135 | 35Crmo | 1.7220 (34CrMo4) | SCM432 |

| 4145H | - | - | - |

Kuumbwa Kwemakemikari

| Muumbi weKemikari (%) | |||||||

| Giredhi | C | Si | Mn | P | S | Cr | Mo |

| 4130 | 0.28-0.33 | 0.15-0.35 | 0.40-0.60 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4140 | 0.38-0.43 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4135 | 0.33-0.38 | 0.15-0.35 | 0.75-0.9 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

| 4145 | 0.43-0.48 | 0.15-0.35 | 0.75-1.0 | ≤0.035 | ≤0.040 | 0.80-1.10 | 0.15-0.25 |

Mechanical Properties

| Hunhu: |

| 1.Low alloy simbi ine molybdenum uye chromium sevanosimbisa vamiririri; |

| 2.Zvakanaka kubva kune fusion weldability maonero; |

| 3.The alloy inogona kuomeswa nekurapa kwekupisa. |

Kushivirira

| Delivery Condition |

| 1.Hot yakakungurutswa |

| 2.Annealed |

| 3.Normalized |

| 4. Kudzima uye kuzvidzora |

Mamiriro ekupisa kupisa

1.Annealing: 880℃ Furnace kutonhora

2.Normalization: 880 ~ 870 ℃ Kutonhora kwemhepo

3.Kuomesa: 820 ~ 870℃ Mvura inotonhorera

4.Tempering: 550 ~ 650℃ Rapid kutonhora

Mechanical Properties inogona kuwanikwa nekusiyana kupisa kurapwa.

Package

1.Nemasumbu, bundle rimwe nerimwe rinorema pasi pematani matatu, kune zviduku zvekunze

dhayamita raundi bha, rimwe nerimwe rine 4 - 8 simbi mitsetse.

2.20 tsoka mudziyo une dimension, kureba pasi pe6000mm

3.40 tsoka mudziyo une dimension, kureba pasi pe12000mm

4.Nemudziyo mukuru, Mutengo wekutakura wakaderera nehuwandu hwekutakura, uye hombe

saizi inorema haigone kutakurwa mumidziyo inogona kutakurwa nekutakura zvinhu zvakawanda

Kuvimbiswa kwehutano

1.Strict maererano neZvinodiwa

2. Muenzaniso: Muenzaniso unowanikwa.

3. Miedzo: Munyu wekupfapfaidza bvunzo / Tensile bvunzo / Eddy ikozvino / Kemikari yekuumbwa bvunzo zvinoenderana nechikumbiro chevatengi

4.Certificate: IATF16949, ISO9001, SGS nezvimwewo.

5. EN 10204 3.1 Chitupa

SAE4130 simbi inotenderera isimbi yemutengo wealloy.Standard ASTMA29/A29M-04.Chirwere chemumba chinoenderana: 30CrMo Inoenderana Chinyorwa cheJapan: SCM430 (SCM2) Inoenderana neGerman brand: 34CrMo4 (1.7220)

4130 simbi yekugadzira ine simba rakawanda uye kuoma, kuomarara kwepamusoro, uye kuomarara kwakaoma dhayamita ye15-70mm mumafuta;Simba rinopisa resimbi rakanakawo, rine simba rakakwana rekushisa riri pasi pe500 ℃, asi simba raro rinoderera zvakanyanya pa550 ℃;Kana iyo alloy element iri pamuganho wakaderera, welding yakanaka chaizvo, asi kana yava pedyo nepamusoro pemuganhu, weldability iri yepakati, uye preheating kusvika pamusoro pe175 ℃ inodiwa tisati tapisa;Simbi ine yakanaka machinability uye ine mwero plasticity panguva inotonhora deformation;Panguva yekurapa kwekupisa, kune kufanana kwehasha brittleness muhuwandu hwe300-350 ℃;Pane katsika kekuita mavara machena.

SAE4130 inonyanya kushandiswa muindasitiri yekugadzira michina yepakati nepakati kugadzira zvikamu zvakadzimirwa uye zvakadzikama zvine mativi makuru emuchinjiko anoshanda pasi pekunetseka kwakanyanya, senge shafts, spindles, uye mavhiri ekudzora mitoro, mabhaudhi, mabhaudhi emusoro maviri, magiya, etc;Inoshandiswa muindasitiri yemakemikari kugadzira zvikamu zvakakandwa, zvivakwa zvakashongedzwa zvinoumbwa nemaplate nemapombi, uye maconduit anotsimbirira ane tembiricha isingadariki 250 ℃ achishanda musvikiro rine nitrogen nehydrogen;Muindasitiri yekugadzira turbines uye boilers, inoshandiswa kugadzira fasteners yebasa iri pasi pe450 ℃, maflange uye maflange anovhara pasi pekumanikidzwa kwakanyanya pasi pe500 ℃.