Comprehensive pickling uyepassivation yesimbi isina tsvina, kubvisa mavara akasiyana-siyana emafuta, ngura, oxide ganda, solder majoini uye imwe tsvina.Mushure mekurapwa, iyo yepamusoro inofanana sirivha chena, inovandudza zvakanyanya kushora kwesimbi isina tsvina, yakakodzera kune akasiyana simbi simbi, mahwendefa uye midziyo.

Zviri nyore kushandisa, zviri nyore kushandisa, zvehupfumi uye zvinoshanda, pamwe nekuwedzera kwe-high-effect corrosion inhibitors kudzivirira kuparara kwesimbi uye hydrogen embrittlement, uye kudzvinyirira chizvarwa che acid mhute.Kunyanya akakodzera madiki uye akaoma workpieces, asina kukodzera kupfekedza, pamusoro pezvigadzirwa zvakafanana pamusika.

Maererano nekuoma kwesimbi isina tsvina uye oxide scale, mhinduro yepakutanga inogona kushandiswa kana kuderedzwa nemvura muchiyero che1: 1: 1-4 isati yashandiswa;Ferrite, Martensite uye austenitic Stainless simbi ine yakaderera nickel content (senge 420.430.200.201.202.300. Mushure me dilution, austenitic Stainless simbi ine yakakwira nickel content (yakadai se304), 321.316.316L mustock ichave soa, etc.)Kazhinji, mushure mekudziya kwakajairika kana kupisa kusvika 50 ~ 60 ℃, sora kwemaminetsi 3-20 kana kupfuura (iyo chaiyo nguva uye tembiricha ichatemwa nemushandisi zvinoenderana nemamiriro ekuedzwa) kudzamara tsvina yepasi yabviswa zvachose, yakaenzana silvery chena. , kugadzira yunifomu uye dense passive film.Mushure mekurapwa, ibudise, woigeza nemvura yakachena, woideredza nemvura ine alkaline kana Limewater.

Iko kudikanwa kwesimbi isina tsvina pickling uye passivation

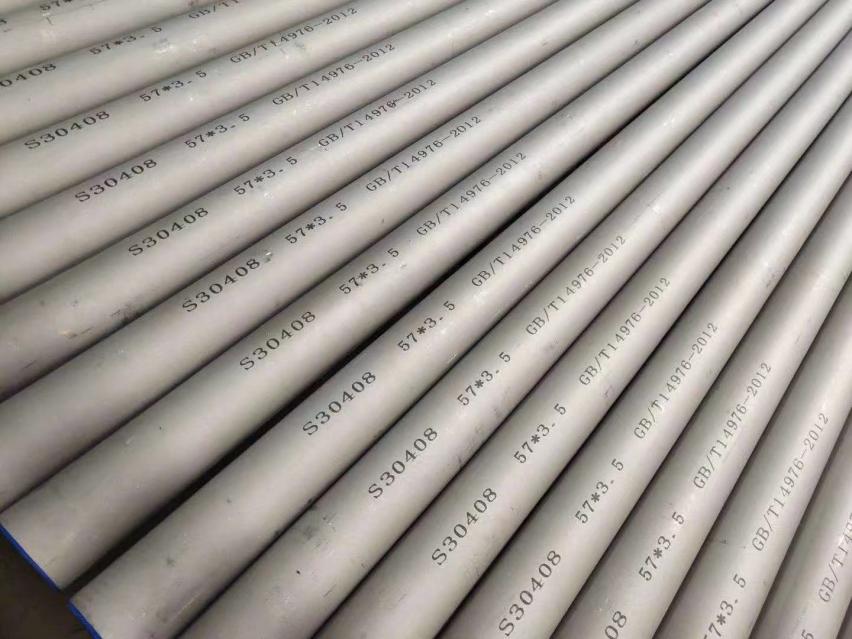

Simbi isina tsvina ine yakanaka corrosion resistance, high-temperature oxidation resistance, yakanaka yakaderera-tembiricha kuita, uye yakanaka mechanic uye R zvivakwa.Naizvozvo, inoshandiswa zvakanyanya mumakemikari, peturu, simba, Nuclear engineering, aerospace, marine, mushonga, indasitiri yemwenje, machira uye mamwe masekete.Chinangwa chayo chikuru ndechekudzivirira kuparara uye ngura.Iyo corrosion resistance yesimbi isina tsvina inonyanya kuenderana nepamusoro passivation firimu.Kana iyo firimu isina kukwana kana kukanganisa, simbi isina tsvina icharamba iine ngura.Acid pickling uye passivation inowanzo shandiswa muinjiniya kusimudzira kushorwa kwesimbi isina tsvina.Munguva yekuumbwa, gungano, welding, weld inspection (yakadai sekuona kukanganisa, muedzo wekumanikidzirwa), uye kuvaka kwekumaka maitiro emidziyo yesimbi isina tsvina uye zvikamu, mavara emafuta epamusoro, ngura, tsvina isina-simbi, yakaderera yakanyunguduka simbi inosvibisa, pendi, welding slag, uye splashes zvinogona kukanganisa pamusoro pemhando yemidziyo yesimbi isina simbi uye zvikamu, kukuvadza iyo oxide firimu pamusoro payo, kuderedza kuzara uye kwepanzvimbo kupera kwesimbi (kusanganisira gomba gora), gap corrosion), uye kunyange kutungamira mukushushikana ngura kuputika. .

Kuchenesa pamusoro pesimbi isina tsvina, pickling uye passivation haingogone kuvandudza corrosion kuramba kusvika pamwero mukuru, asiwo kudzivirira kusvibiswa kwechigadzirwa uye kuwana aesthetic mhedzisiro.GBl50-1998 "Steel Pressure Vessels" inotaura kuti pamusoro pemidziyo yakagadzirwa nesimbi isina tsvina uye mahwendefa esimbi anoumbwa anofanirwa kubikwa uye kupfuudzwa.Uyu murairo unoshanda kune midziyo yekumanikidza inoshandiswa mu petrochemical industry.Sezvo midziyo iyi ichishandiswa mumamiriro ezvinhu apo inosangana yakananga neyakaora midhiya, zvinodikanwa kuti utaure acid pickling uye passivation kubva pakuona kwekuona kusaita ngura uye kusagadzikana kwemarara.Kune mamwe maindasitiri maindasitiri, kana isiri yekudzivirira ngura, inongobva pane zvinodiwa zvehutsanana uye aesthetics, nepo simbi isina tsvina haidi pickling uye passivation.Asi ma welds emidziyo yesimbi isina tsvina inodawo pickling uye passivation Kune mamwe makemikari midziyo ine zvinodikanwa zvekushandisa, kunze kwekunatswa kweasidhi uye passivation, yakakwira kuchena svikiro ichashandiswawo pakuchenesa kwekupedzisira kana kuchenesa michina, kupedzisa chemistry uye Electropolishing.

Nheyo dzeStainless Simbi Pickling uye Passivation

Kudzivirirwa kwekuora kwesimbi isina tsvina kunonyanya kukonzerwa nekuti iyo nzvimbo yakafukidzwa neyakaonda zvakanyanya (inenge 1) nm) dense passivation firimu, iyo inoparadzanisa svikiro inoparadza uye inoshanda seyakakosha chipingamupinyi chekudzivirira simbi isina tsvina.Stainless simbi passivation ine hunhu hunochinja uye haifanirwe kutorwa sekupera zvachose kwekuora.Pane kudaro, diffusion barrier layer inofanira kuumbwa, ichideredza zvakanyanya anode reaction rate.Kazhinji, kana pane inoderedza mumiririri (yakadai sekloridi ions), membrane inowanzokuvadza, uye kana pane oxidizing agent (yakadai semhepo), membrane inogona kuchengetedzwa kana kugadziriswa.

Stainless simbi workpieces yakaiswa mumhepo ichaita oxide firimu, asi kudzivirira kwavo hakuna kukwana.Kazhinji, kucheneswa kwakakwana kunoitwa kutanga, kusanganisira alkaline uye asidhi yekugeza, inoteverwa nepassivation ine oxidant kuti ive nechokwadi chekutendeseka uye kugadzikana kweiyo passivation firimu.Chimwe chezvinangwa zve pickling kugadzira mamiriro akanaka ekurapa kwepassivation uye kuve nechokwadi chekugadzirwa kwemafirimu emhando yepamusoro passivation.Acid washing inokonzera ngura pamusoro pesimbi isina tsvina ine avhareji ukobvu hwe10m.Mushonga wemakemikari wemushonga weasidhi unokonzera kunyunguduka kwenzvimbo yakakanganisika kuti ive yakakwirira kudarika yezvimwe zvikamu zvepasi.Naizvozvo, kugezwa kweasidhi kunogona kuita kuti nzvimbo yese ienzane uye kubvisa dzimwe njodzi dzinogona kuita ngura.Asi zvinonyanya kukosha ndezvokuti, kuburikidza nekunhonga kweasidhi uye passivation, iron uye iron oxides inonyungudika kupfuura chromium uye chromium oxides, ichibvisa urombo hwechromium layer, zvichikonzera hupfumi hwechromium pamusoro pesimbi isina tsvina.Iko kugona kweiyo yakapfuma chromium passivation firimu inogona kusvika + 1.0V (SCE), iri padyo nekugona kwesimbi dzakakosha uye inovandudza kugadzikana kwekupokana kwekuora.Kurapa kwakasiyana-siyana kunogona kukanganisawo kuumbwa uye chimiro chefirimu, nekudaro zvichikanganisa kushora kwayo.Semuenzaniso, kuburikidza ne electrochemical modification kurapwa, iyo passivation firimu inogona kuve neakawanda-layer chimiro uye fomu CrO3 kana Cr2O3 mubarriers layer, kana kuumba girazi reokisi firimu kuti riwedzere kusimba kwekuora kwesimbi isina tsvina.

1.Stainless simbi pickling uye passivation nzira

Iyo impregnation nzira inoshandiswa kune zvikamu zvinogona kuiswa mu pickling kana passivation matangi, asi haina kukodzera kushandiswa kwenguva refu kwepickling solution mumidziyo mikuru, ine hunyanzvi hwekugadzira uye mutengo wakaderera;Iyo hombe vhoriyamu midziyo yakazadzwa neasidhi mhinduro, uye kunyudzwa kwemvura kushandiswa kwakanyanya.

Inokodzera mukati mepamusoro uye emunharaunda mashandiro emuviri wemidziyo mikuru.Mamiriro ekushanda asina kunaka uye kusakwanisa kudzoreredza mhinduro yeasidhi.

Nzira yekuisa inoshandiswa pakuisa kana kugadzirisa nzvimbo, kunyanya kushandiswa kwemaoko mudhipatimendi rekushongedza.Mamiriro evashandi haana kunaka uye mutengo wekugadzira wakakwira.

Iyo yekupfapfaidza nzira inoshandiswa panzvimbo yekuisa, ine yakaderera mvura vhoriyamu pamadziro emukati emidziyo mikuru, yakaderera mutengo, uye nekukurumidza kukurumidza, asi inoda kumisikidzwa kwepfuti yekupfapfaidza uye yekutenderera system.

Iyo nzira yekutenderera inoshandiswa kune yakakura-yakakura michina, yakadai seyekupisa.Iko kuvakwa kwechubhu uye ganda kurapwa kuri nyore, uye iyo acid mhinduro inogona kushandiswa zvakare.Inoda pombi uye kubatana kwepombi kune inotenderera system.

Electrochemical nzira haigone kushandiswa chete kune zvikamu, asiwo pakurapa kwepamusoro kwe-on-saiti zvishandiso.Iyo tekinoroji yakaoma uye inoda DC magetsi kana potentiostat.

2.Pickling uye passivation maitiro

Kubvisa uye kuchenesa tsvina → Kugeza chikamu chekuchenesa mvura → Kufambisa → Kugeza nemvura yakachena → Kufuridza yakaoma

3.Pretreatment pamberi pickling uye passivation

3.1 Zvinoenderana nezvinodiwa zvekudhirowa uye magwaro ekugadzirisa, ita acid pickling uye passivation pre-kurapa pamidziyo yesimbi isina tsvina kana zvikamu mushure mekugadzira.

3. Weld seam uye welding slag kumativi ose maviri.Chenesa masplashes, uye shandisa peturu kana yekuchenesa dhizaini kubvisa mavara emafuta uye imwe tsvina pamusoro pemidziyo yekugadzira midziyo.

3.3 Paunenge uchibvisa zvinhu zvekunze kumativi ese eweld seam, shandisa simbi isina tsvina yewaya bhurasho, foshoro yesimbi isina tsvina kana vhiri rekukuya kuti uzvibvise, wozvigeza nemvura yakachena (ine chloride ion content isingadariki 25mg/l).

Kana kusvibiswa kwemafuta kwakanyanya, shandisa 3-5% alkaline solution kuti ubvise tsvina yemafuta uye usuke zvakanaka nemvura yakachena.

3. Mechanical jecha blasting inogona kubvisa ganda reoxide resimbi isina tsvina Inopisa zvikamu zvekushanda, uye jecha rinofanira kuva rakachena silicon kana aluminium oxide.

3.6 Gadzira matanho ekuchengetedza ekunhonga uye passivation, uye tarisa maturusi anodiwa nemidziyo yekudzivirira yevashandi.

4.Acid pickling, passivation solution uye paste formula

4.1 Acid washing solution formula: nitric acid (1).42) 20%, hydrofluoric acid 5%, uye imwe yese imvura.Iri pamusoro ihuwandu hwehuwandu.

4.2 Acid yekuchenesa cream formula: 20 milliliters yehydrochloric acid (chiyero 1.19), 100 milliliters emvura, 30 milliliters ye nitric acid (reshiyo 1.42), uye 150 gramu ye bentonite.

4. Passivation solution formula: nitric acid (chiyero 1).42) 5%, Potassium dichromate 4g, yasara imvura.Iyo iri pamusoro pezana yekudonha, passivation tembiricha itembiricha yekamuri.

4.4 Passivation paste formula: 30ml nitric acid (concentration 67%), 4g Potassium dichromate, wedzera bentonite (100-200 mesh) uye simbisa kuti unamate.

5.Acid pickling uye passivation operation

5.1 Chete midziyo kana zvikamu zvakatora pickling uye passivation pre-kurapwa zvinogona kuita pickling uye passivation.

5. 2 Acid pickling solution inonyanya kushandiswa pakurapa kwese kwezvikamu zviduku zvisina kugadziriswa, uye zvinogona kupfapfaidzwa.Iyo tembiricha yemhinduro inofanirwa kuongororwa maminetsi ega ega patembiricha ye21-60 ℃ kusvika yunifomu chena asidhi etching kupera iripo.

5.3 Pickling paste Pickling inonyanya kukodzera midziyo mihombe kana kugadziriswa kwenzvimbo.Patembiricha yemumba, chenesa zvakaenzana paste yepickling pamidziyo (inenge 2-3mm gobvu), isiye kweawa imwe, uye zvinyoro nyoro bhurasha nemvura kana simbi isina tsvina waya bhurasho kusvikira yunifomu chena asidhi etching kupera kuoneka.

5.4 Passivation mhinduro inonyanya kukodzera kurapwa kwese kwemidziyo midiki kana zvikamu, uye inogona kunyudzwa kana kupfapfaidza.Kana tembiricha yemhinduro iri 48-60 ℃, tarisa maminetsi makumi maviri ega ega, uye kana tembiricha yemhinduro iri 21-47 ℃, tarisa awa yega kusvika yunifomu passivation firimu yaumbwa pamusoro.

5.5 Passivation paste inonyanya kukodzera midziyo mikuru kana kugadzirisa kwenzvimbo.Inoshandiswa zvakaenzana pamusoro pechigadziko chakakanyiwa (inenge 2-3mm) pane tembiricha yekamuri uye inoongororwa kweawa imwe kusvikira yunifomu passivation firimu inoumbwa pamusoro.

5.6 Acid pickling uye passivation midziyo kana zvikamu zvinofanirwa kugezwa nemvura yakachena pamusoro., Shandisa acidic litmus test bepa kuyedza chero chikamu chenzvimbo yakagezwa, kuitira kugezesa pasi nemvura ine pH kukosha pakati pe6.5 ne7.5, wozopukuta kana kupukuta nemhepo yakamanikidzwa.

5.7.Mushure mekutora uye passivation, zvinorambidzwa kukwenya iyo passivation firimu paunenge uchibata, uchisimudza, uye uchichengeta midziyo uye zvikamu.

Nguva yekutumira: Aug-08-2023